The manufacturing of crane kits has seen huge developments throughout the long term, especially in the reconciliation of electric hoists. These progressions have changed the idea of lifting and moving weighty burdens, making processes more productive and protected across different enterprises. Electric hoists, which utilize electric ability to lift and lower loads, have become basic parts in crane kits, considering upgraded execution and unwavering quality contrasted with conventional manual frameworks. The excursion from idea to reality in this area includes different stages, including configuration, designing, and mechanical combination, all pointed toward satisfying the developing needs of current industry. At first, the idea of electric hoists was conceived out of the requirement for more secure and more productive lifting arrangements. Conventional lifting techniques, which frequently depended on human strength or awkward mechanical frameworks, presented dangers and shortcomings. As the business advanced, engineers started to investigate the capability of electric ability to smooth out lifting tasks. This investigation prompted advancements in engine innovation, control frameworks, and security highlights, permitting electric hoists to lift heavier burdens with more noteworthy accuracy and less exertion.

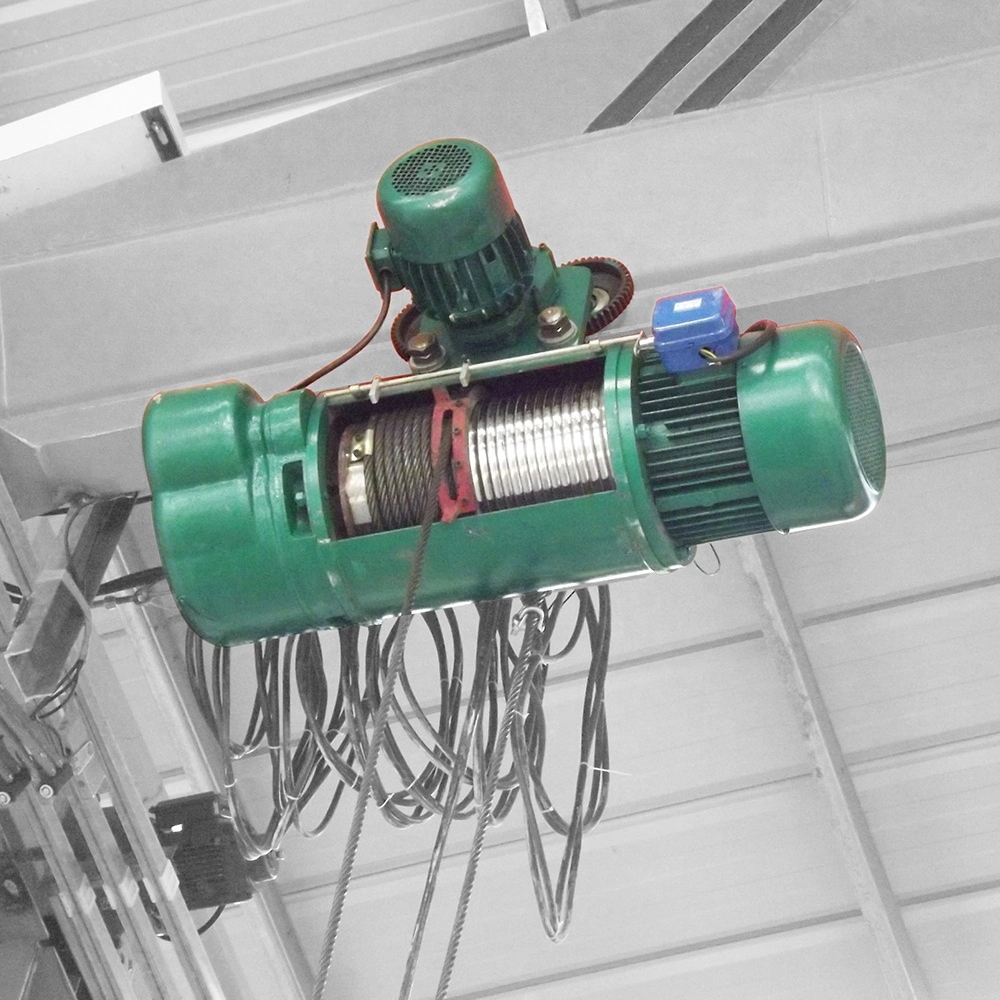

In the plan stage, makers center around making electric hoists that are strong as well as minimal and lightweight. This is fundamental for crane kits, which require parts that can be handily incorporated without compromising the general construction. High level materials, for example, high-strength composites and polymers, are frequently used to lessen weight while keeping up with solidness. Besides, plan engineers utilize PC helped plan computer aided design programming to demonstrate and mimic crane execution under different circumstances, guaranteeing that the end result can withstand the afflictions of modern use. The designing system additionally includes thorough testing and approval. Before electric hoists can be integrated into crane kits, they go through broad wellbeing testing to satisfy administrative guidelines. This incorporates assessing load limits, functional unwavering quality, and crisis highlights, like over-burden insurance and slowing mechanisms. These tests guarantee that the electric hoists can perform securely in certifiable applications, limiting the gamble of mishaps and wounds. Mechanical reconciliation plays had a crucial impact in the development of electric hoists inside crane kits. The joining of brilliant innovation has empowered highlights like controller activity, ongoing burden checking, and diagnostics.

These headways upgrade functional effectiveness as well as take into consideration prescient upkeep, which can fundamentally diminish margin time and support costs. Moreover, the utilization of remote innovation works with more noteworthy adaptability in tasks, empowering administrators to control hoists from a protected distance. Besides, supportability has arisen as a basic thought in the improvement of electric hoists. Producers are progressively taking on eco-accommodating practices, like utilizing energy-proficient engines and recyclable materials. This shift tends to natural worries as well as requests to ventures taking a stab at greener tasks. All in all, the excursion from idea to reality in the manufacturing of crane kits with electric hoists includes a mind boggling transaction of plan development, designing thoroughness, and mechanical headway. These polipsto eléctrico de cadena improvements have altered lifting activities, upgrading wellbeing, effectiveness, and supportability in different modern applications. As the business keeps on developing, further advancements are supposed to arise, making ready for considerably further developed electric derrick frameworks in crane kits.